Reliable solutions for cutting corrugated plastic materials

Want to discover 5 ways to make money with a Kongsberg cutting table?

Download this free guide today!

Want to discover 5 ways to make money with a Kongsberg cutting table?

Download this free guide today!

Cutting corrugated plastic is a key part of producing durable, lightweight signage, packaging, and display materials. Corrugated plastic is a twin-wall polypropylene sheet used widely across industries thanks to its weather resistance, rigidity, and cost-effectiveness. While it’s a popular material, especially in retail signage, real estate boards, and reusable packaging, its structure poses specific challenges when it comes to precision cutting, creasing, and folding.

Cutting corrugated plastic is a key part of producing durable, lightweight signage, packaging, and display materials. Corrugated plastic is a twin-wall polypropylene sheet used widely across industries thanks to its weather resistance, rigidity, and cost-effectiveness. While it’s a popular material, especially in retail signage, real estate boards, and reusable packaging, its structure poses specific challenges when it comes to precision cutting, creasing, and folding.

To consistently achieve clean cuts, crisp folds, and production-ready parts, manufacturers and signmakers need the right digital cutting solution. Kongsberg Precision Cutting Systems delivers exactly that: precision, speed, and reliability through advanced technology built for performance.

Kongsberg PCS understands the demands of modern production environments. Our systems are engineered to overcome the specific challenges of working with corrugated plastic. With over 60 years of experience and a commitment to innovation, we design tools and tables that improve throughput, reduce errors, and maintain the highest cut quality.

Whether you're producing high-volume signage or custom packaging, Kongsberg PCS offers cutting tables built to handle corrugated plastic with speed and accuracy. Our modular systems adapt to your production needs and are trusted by converters, signmakers, and display specialists worldwide.

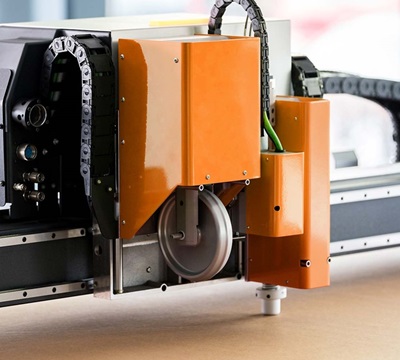

The Kongsberg Ultimate is our flagship digital cutting table, engineered for industrial strength and unmatched throughput. It’s designed to keep pace with the most demanding environments, offering precision and reliability in every cut.

The Kongsberg C series combines versatility and performance in a compact footprint, perfect for businesses needing flexible production without sacrificing speed or quality.

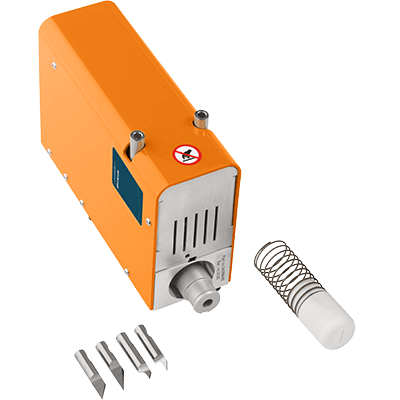

High frequency VibraCut knife tool: ideal for fast, accurate cutting of corrugated plastic; uses a vibrating motion to slice cleanly through tough fluted materials with no tearing.

High frequency VibraCut knife tool: ideal for fast, accurate cutting of corrugated plastic; uses a vibrating motion to slice cleanly through tough fluted materials with no tearing.Corrugated plastic is a versatile but demanding material. To cut it cleanly and efficiently, you need a system that offers more than just cutting—it needs to handle creasing, V-notching, and high-speed runs without sacrificing quality.

Kongsberg Precision Cutting Systems gives you the edge. With industry-leading hardware, intelligent software, and advanced tooling, our solutions let you move faster, waste less, and deliver better results. Whether you’re a high-volume packaging producer or a sign shop working with diverse materials, we have the cutting table and tools to fit your needs—and grow with your business.

Discover how Kongsberg PCS can help you cut corrugated plastic with confidence. Get in touch with our team today to explore the possibilities.

Do you want more information? Would you like to schedule a demo? Just feel like chatting?

We are here for you! Just leave your contact info below and we'll get back to you.