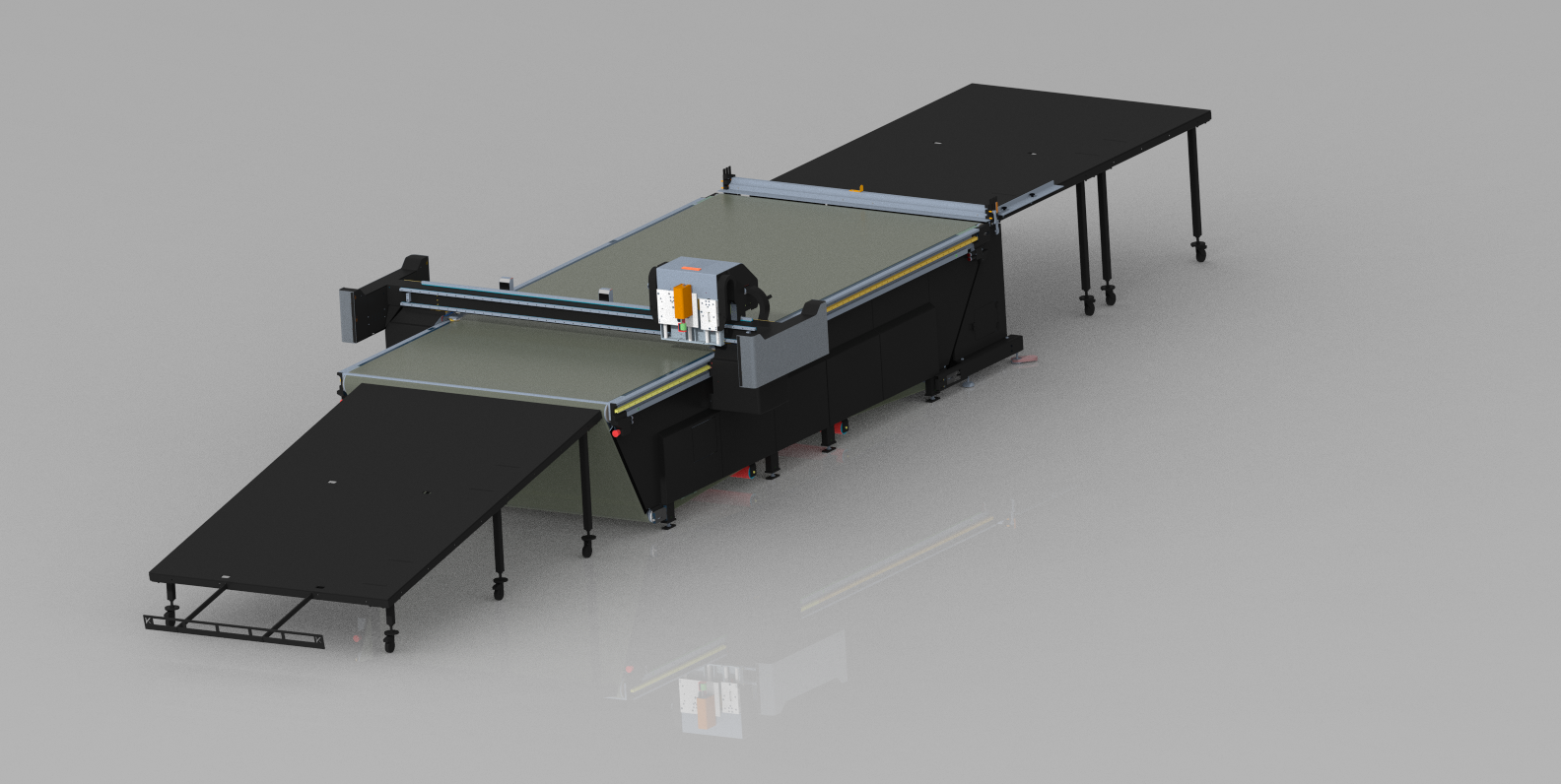

Smart Material Handler

The Smart Material Handler (SMH) is a modular handling solution for Kongsberg tables. It guides the flow of materials with operator assistance, shortens idle time, and keeps jobs progressing between cuts.

Smart Material Handler keeps the table cutting while the next sheet is prepared. Operators stage the next job as the current sheet finishes. The dedicated offload area collects finished work and supports a smooth handover to the next process.

SMH reduces manual touches and balances speed with control. A single operator can manage the cycle from load to offload. With the optional Under Side Camera, registration and positioning are detected to keep work accurate and consistent.

Key benefits:

Looking for unattended pallet to pallet automation instead? See Feeder & Stacker or Robotic Material Handler.

Good to know

Cycle time is easiest to maintain with jobs longer than 20 seconds. Stacking on the offload table depends on material and job complexity.

| Widths: 2x, 4x, 6x |

| Orientation: landscape and portrait |

| Under Side Camera: optional for registration on print-side-down jobs |

| Offload: fixed 12° angle with extendable stoppers |

| Retrofit: supported on C and Ultimate |

| Rollfeeder: quick swap ready |

(Sheet size capability follows the connected cutting table specification.)

Get in touch with one of our experts. We're here to help you cut smarter, faster and better.