Benefits you won’t find anywhere else

- Consistent wrinkle-free and straight feed

- Always in perfect registration with the print

- Capable of handling heavy rolls up to 300 kg/660 lbs

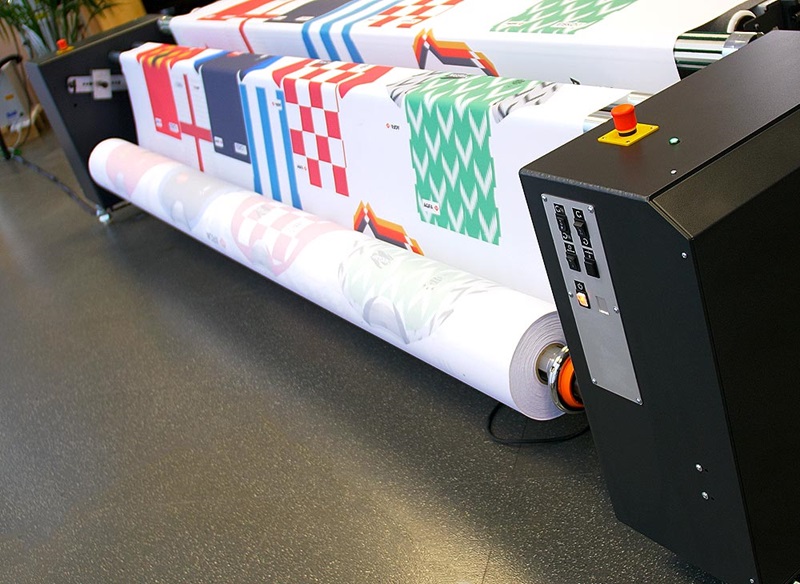

The Motorized Roll Feeder is your ticket to continuous production of high volumes of wide format soft signage jobs. Innovative features work together to achieve the perfect final cut, even on challenging and tensile substrates.

The unique combination of the Motorized Roll Feeder and the built-in Kongsberg iPC software cleverly compensates for any distortion.

The curve registration algorithm determines the exact cut size, taking material properties for shrink, stretch or melting during the printing stage into account.

Alternatively, the operator can decide to follow what was printed.

Since there is a compensation type that fits every job, expensive reprints due to inaccurate cuts are now truly a thing of the past.

The finishing department keeps up with the current digital printing capacity. Handle heavy rolls up to 300 kg (660 lbs) maximum outer diameter of 470 mm (18.5 in.).

Produce high volumes of large jobs, long print runs, dense materials like PVC, and jobs longer than table, uninterrupted and with invisible joints.

The Motorized Roll Feeder guarantees consistent wrinkle-free and straight feed onto the Kongsberg C64 cutting table. It avoids stretch by actively feeding material to the cutting table, rather than pulling it. The Motorized Roll Feeder supports clockwise and counter-clockwise winding and manual rewind.

The dancer bar provides correct tension with adjustable weights for different materials. It sends a signal to the motor-driven shaft to advance material. This is yet another way to feed the material wrinkle-free, rather than pulling it.

It’s challenging to have a straight roll after printing. The active edge correction allows for a steady straight feed, even if the roll is imperfectly rewound after printing. It senses, and subsequently corrects, the position of the material on the shaft. Edge correction goes as far as 5 cm (2 in.).

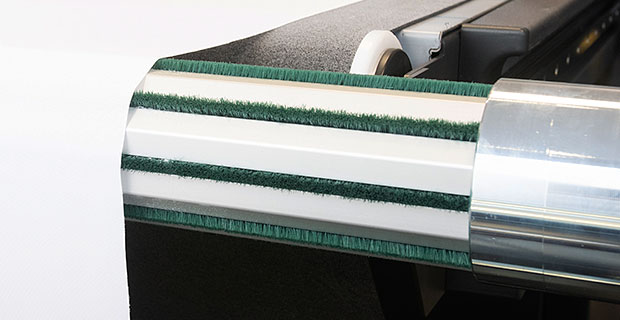

The bidirectional brushes on the spreader roll smooth out any remaining wrinkles before the conveyor belt on the cutting table picks up the material. The spreader roll is the final checkpoint to guarantee wrinkle-free feed before the conveyor belt on the table picks up the material for precise finishing.

The conveyor belt on the Kongsberg C64 cutting table continues the flat feed of material during the cutting stage. It moves smoothly over the table top, eliminating wrinkles or folds. The conveyor belt advances straight at all times, ensuring the cut is in perfect registration with the print.

The Motorized Roll Feeder moves on wheels and docks to the Kongsberg cutting table with powerful magnets. It's simple to load and very intuitive to operate.

Use unique barcodes to automate continuous production and increase throughput. The camera reads the printed barcode, allowing the built-in Kongsberg iPC software to identify the job.

If tension control is not crucial, with lighter rolls and shorter print runs, for instance, the Motorized Roll Feeder equally serves as a passive roll-off. Simply place the roll on the two top rollers and let the conveyor belt drag the material onto the table.

When used in combination with the Kongsberg Take-Up Unit, the Motorized Roll Feeder enables true roll-to-roll production. The Take-Up Unit separates the waste from the finished material by collecting the finished product in the basket and winding the waste substrate onto another roll.

| Roll max. width: 3210 mm – 126.38 in. |

| Roll max. diam.: 470 mm - 18½ in. |

| Max. roll weight: 300 kg – 660 lbs |

| Max winding speed: 23 m/min – 15 IPS |

| Edge Correction: Up to 50 mm – 2 in. |

| Weight: 450 kg – 990 lbs |

| Overall dimensions: W: 4215 mm - 166 in. D: 675 mm - 26½ in. H: 950 mm - 37½ in. |

| Power supply: 220V/50Hz or 110V/60Hz |

Do you want more information? Would you like to schedule a demo? Just feel like chatting?

We are here for you! Just leave your contact info below and we'll get back to you.