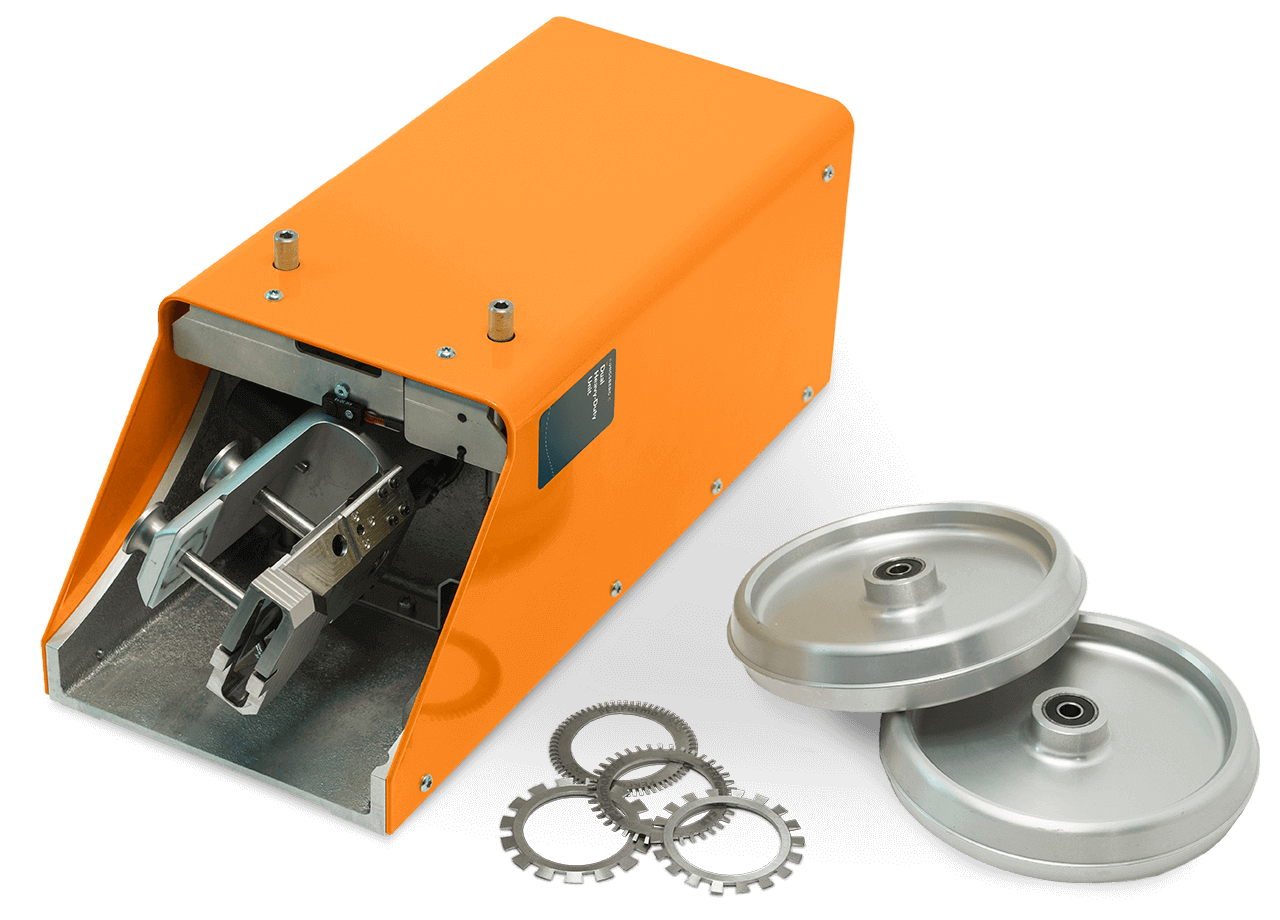

Dual heavy duty unit

The Dual Heavy Duty Unit makes it possible to cut, crease and perforate a single job without the need to change tools.

Interested in this tool, or do you want to find out more about our impressive range of tools? Contact our specialists today!