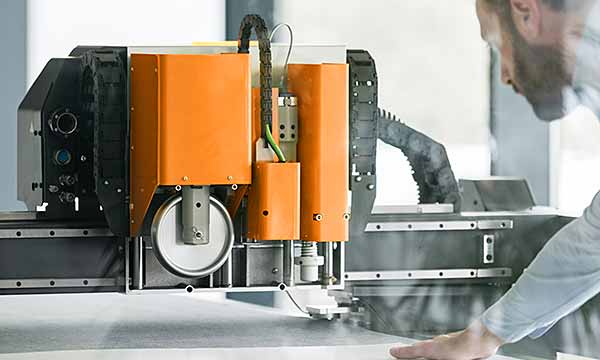

Protective packaging production

Using protective packaging made of corrugated and foam material reduces the weight of cargo with more than 50% compared to wooden crates. The time to cut and mount a corrugated box with foam inserts normally takes up about 30% of the time it takes to create a wooden container.

Kongsberg cutting tables are well suited to produce protective packaging!