Features

Want to talk to a specialist? Just leave your contact info and we'll get back to you.

The MultiCUT-HS spindle is the perfect option for a shop who want to support a wide variety materials and applications with minimal change over time. The head allows you to jump from kiss cutting vinyl to milling ACM without the need for any manual intervention and still delivers an extremely high-quality finish.

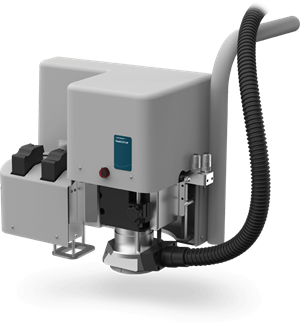

The MultiCUT-HP (High Power) is equipped with a super-strong, liquid-cooled milling spindle delivering several times higher productivity than less powerful alternatives. This is a great choice for shops who need extended milling duty cycles and/or who work extensively with heavy-duty materials (thick sheets of acrylic, wood/MDF and aluminium composite material).

The FlexiHead offers highly accurate, powerful cutting on all flexible and thin materials (paper, folding carton, textile, vinyl...). Three configurable tool stations accommodate a full range of standard tool inserts. Specially designed knife and crease tool inserts are available to produce folding cartons with the same high throughput as corrugated jobs.

The PowerHead excels on heavy duty material (honeycomb boards, triple wall and recycled board...). It features 150 mm (6“) diameter crease wheels and additional scoring pressure with the equivalent of 50 kg (110 lbs) down force. The large wheels enable creasing high recycle content boards without breaking the liner. The knife adapter also offers V-notch cutting, enabling mitered and extremely precise folds when producing heavy-duty containers and paper core board displays.

The FoamHead uses a reciprocating knife to handle foam materials with a maximum thickness of 86 mm [3⅜”]. With serrated-edge blades, it can also manage thick honeycomb paperboard. Three blade adapters control the blade length so it can be matched to material thickness. And, it is easy to program accurate partial through cuts thanks to the advanced Z-axis control.

| X20 | X22 | X24 | X44 | X46 | X48 | ||

| Work area, all tools |

1680 x 1270 66 x 50 |

1680 x 2190 66 x 86 |

1680 x 3200 66 x 126 |

2210 x 3200 87 x 126 |

2210 x 4800 87 x 189 |

2210 x 6550 87 x 258 |

mm in. |

| Max. material size | 1740 x 1750 68 x 69 |

1740 x 2570 68 x 101 |

1740 x 3575 68 x 140 |

2270 x 3575 89 x 140 |

2270 x 5250 89 x 206 |

2270 x 6930 89 x 273 |

mm in. |

| Max. material width, w/ conveyor system | 1680 66 |

1680 66 |

1680 66 |

2210 87 |

2210 87 |

n/a | mm in. |

| Overall dimensions w/ front panel |

2780 x 2450 109½ x 96½ |

2780 x 3040 109½ x 119½ |

2780 x 4050 109½ x 159½ |

3300 x 4050 130 x 159½ |

n/a | n/a | mm in. |

| Overall dimensions w/ revolving workstation |

3600 x 2160 141¾ x 85 |

3600 x 2950 141¾ x 116 |

3600 x 3960 141¾ x 156 |

4070 x 3960 160¼ x 156 |

4070 x 5640 160¼ x 222 |

4070 x 7320 160¼ x 288¼ |

mm in. |

| Weight | 455 1000 |

525 1150 |

630 1390 |

815 1800 |

1150 2540 |

1485 3270 |

kg lbs |

| Max. speed | 50 833 33 |

m/min mm/sec IPS |

|||||

| Max. acceleration | 0.56 G | 0.54 G |

|||||

| Vacuum sections | 2 | 4 | |||||

| Standard traverse clearance (excl. cutting underlay) | 50 2 |

mm in. |

|||||

| Optional traverse clearance (excl. cutting underlay) |

95 3¾ |

mm in. |

|||||

We are here for you! Just leave your contact info and we'll get back to you.