The most versatile corrugated board cutters on the market today

Want to discover 5 ways to make money with a Kongsberg cutting table?

Download this free guide today!

Want to discover 5 ways to make money with a Kongsberg cutting table?

Download this free guide today!

Corrugated board cutting plays a vital role in packaging, point-of-sale displays, and sample production, but it comes with specific hurdles: variable board thickness, crushing flutes, warped sheets, and time-consuming die processes. Tackling these issues effectively depends on using a purpose-built corrugated board cutter designed for precision and flexibility. The right system reduces manual cutting errors with digital accuracy and prevents liner crushing through controlled downforce. It also enables intricate shapes and creases to be created in a single automated pass and accelerates prototype and short-run workflows by eliminating the need for die tooling.

Here’s how the right system can transform your workflow:

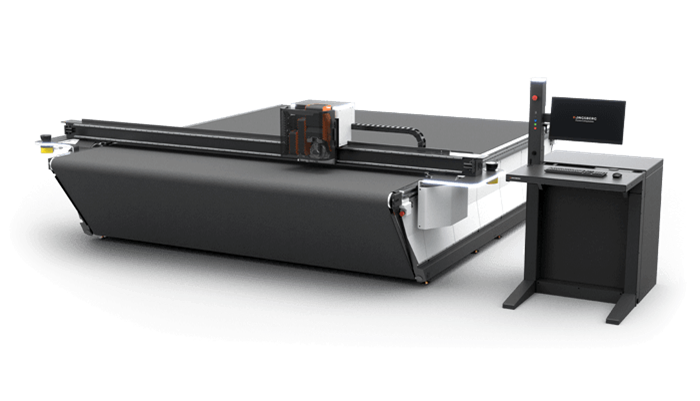

With over six decades of innovation, Kongsberg Precision Cutting Systems delivers advanced and trusted solutions tailored to corrugated board. Our systems combine robust build quality with intelligent automation to help businesses stay agile and efficient.

Why businesses choose Kongsberg PCS:

In addition to these core advantages, Kongsberg systems offer high-speed cutting capabilities that drive faster throughput. They are natively compatible with major packaging design software, streamlining your workflow from concept to production. Automatic tool recognition helps reduce setup errors, while scalable configurations support everything from prototyping to full-scale industrial production. Integrated safety systems protect operators throughout the process, and our global support network ensures you have fast, expert service whenever and wherever you need it.

Our range of cutting tables is optimized to meet different demands, whether it’s speed, versatility or scale. here’s a snapshot:

Correct tooling is critical to maintain board integrity and achieve clean cuts. kongsberg offers several dedicated tools for corrugated materials:

Each tool features automatic recognition, precise pressure settings, and easy changeover, helping you switch between tasks without guesswork.

Choosing kongsberg pcs means gaining more than just machines, you get a partner for corrugated board innovation and growth. our digital cutters and tooling help you:

Ready to refine your corrugated board cutting? Contact kongsberg pcs today to find a tailored solution that enhances your production, creativity and bottom line.

Get in touch with one of our experts. We're here to help you cut smarter, faster and better.