Limitless versatility

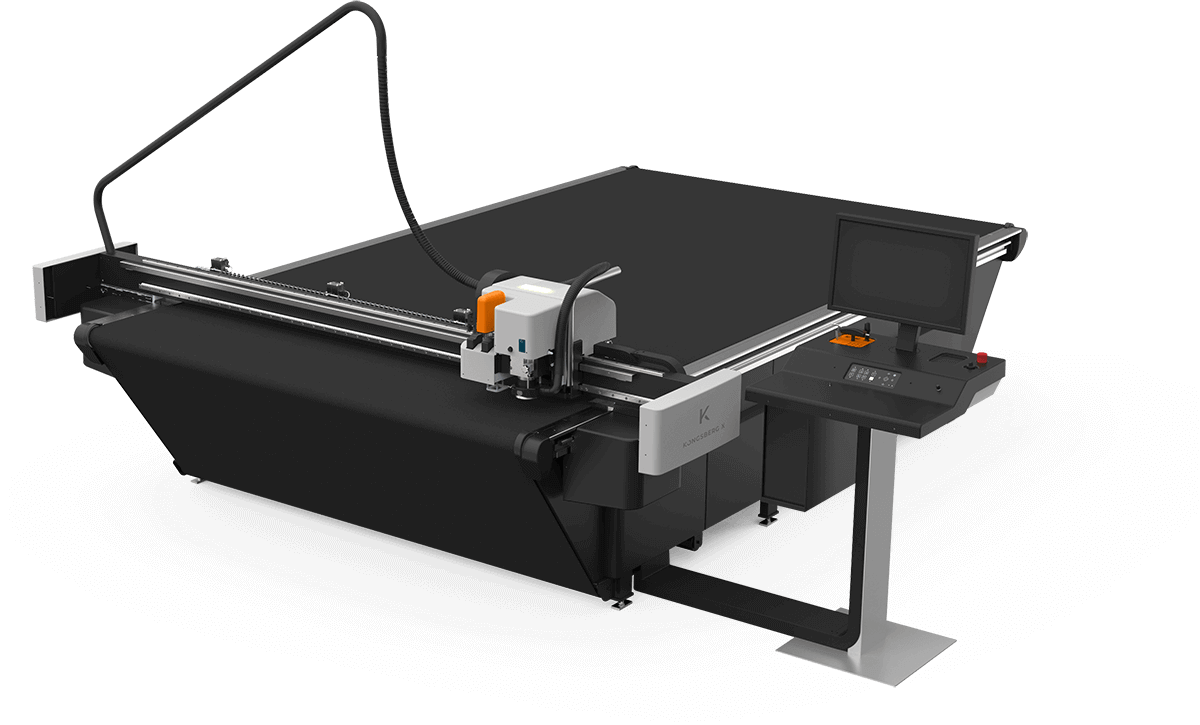

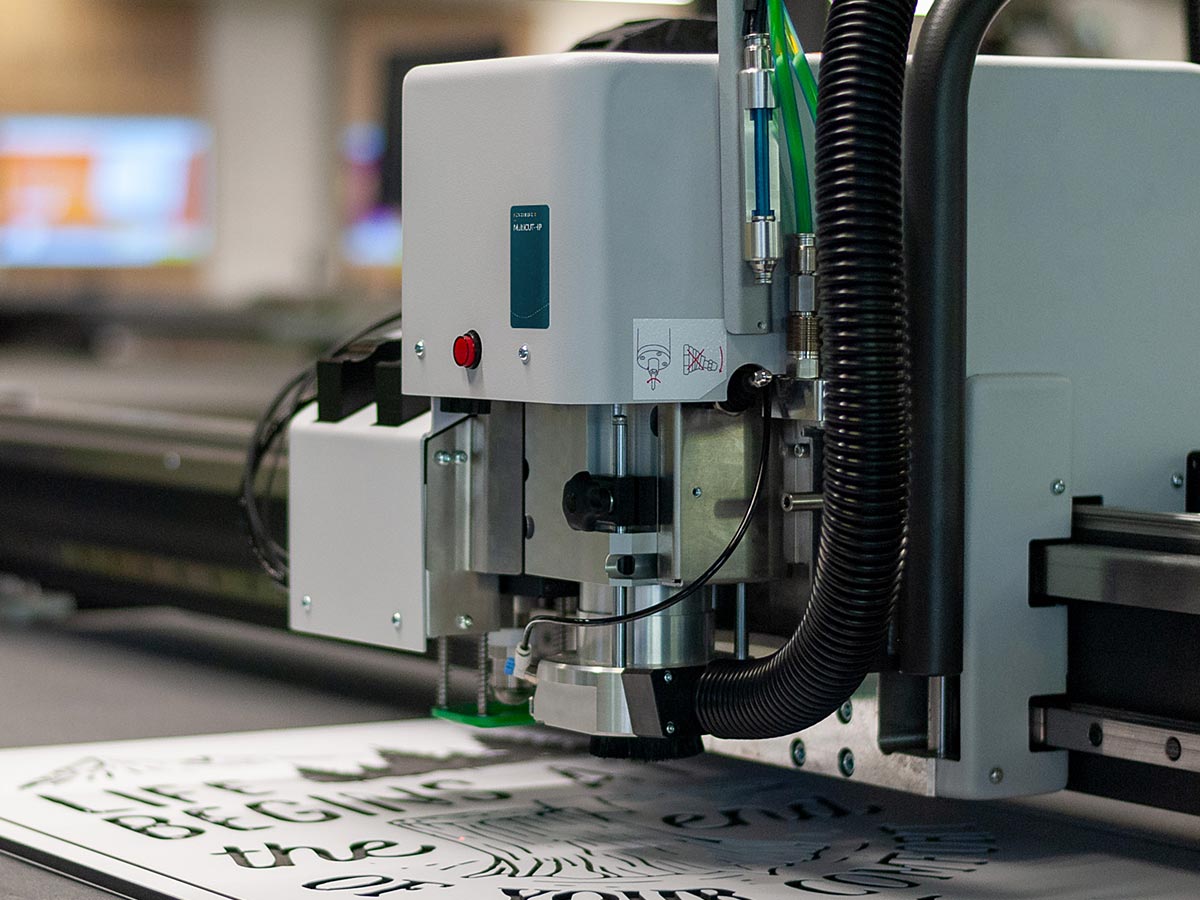

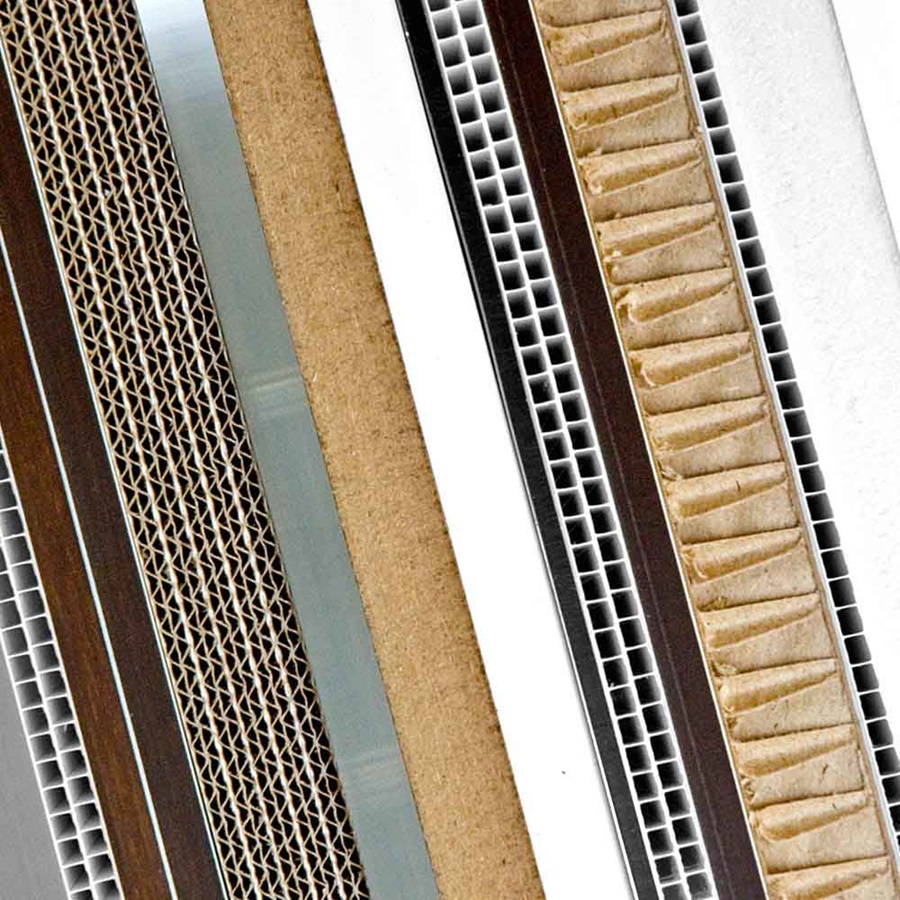

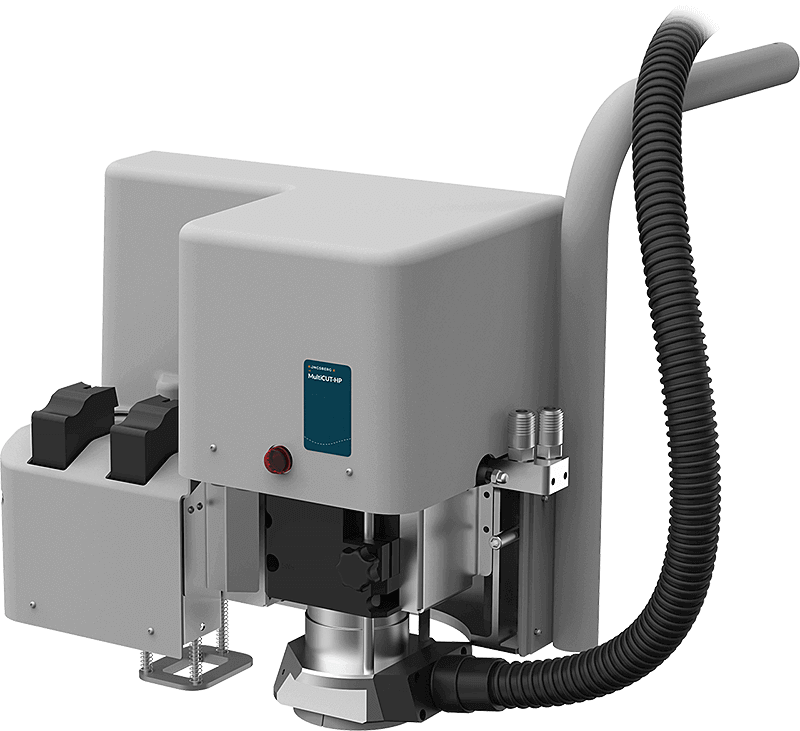

The Kongsberg X cutting table evolves with the needs of your company and offers versatility for a wide range of cutting applications, whether your focus is 2D or 3D; packaging, signs or displays.

Want to talk to a specialist? Just leave your contact info and we'll get back to you.