Let's discuss

Want to talk to a specialist? Just leave your contact info below and we'll get back to you.

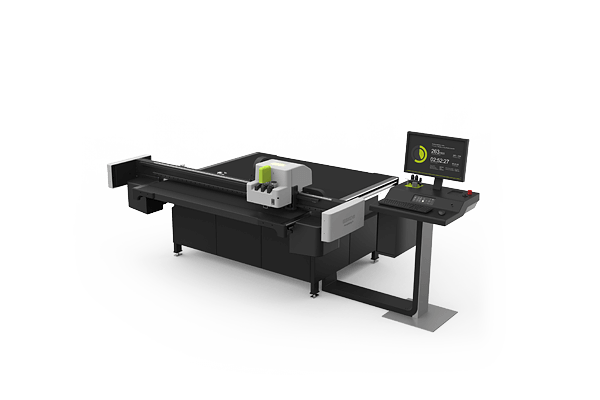

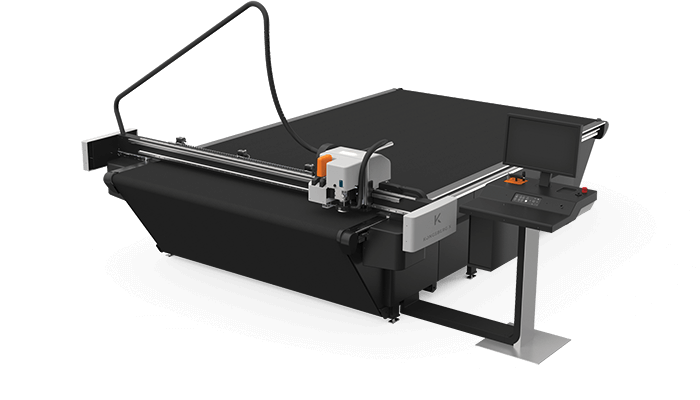

The Kongsberg X offers versatility for a wide range of cutting applications.

Whether your focus is 2D or 3D, or packaging, signs or displays with just about any material from vinyl over paper board to wood; the Kongsberg X is perfect for any job or application.

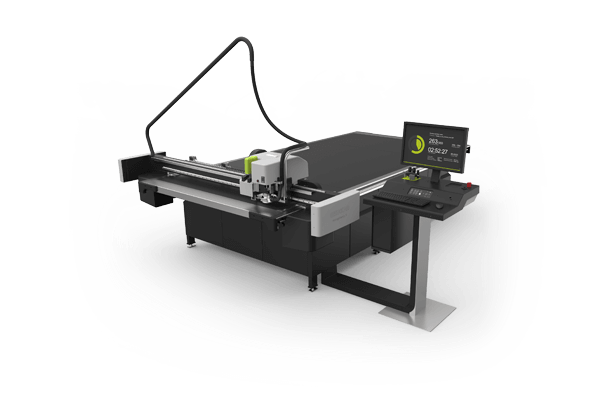

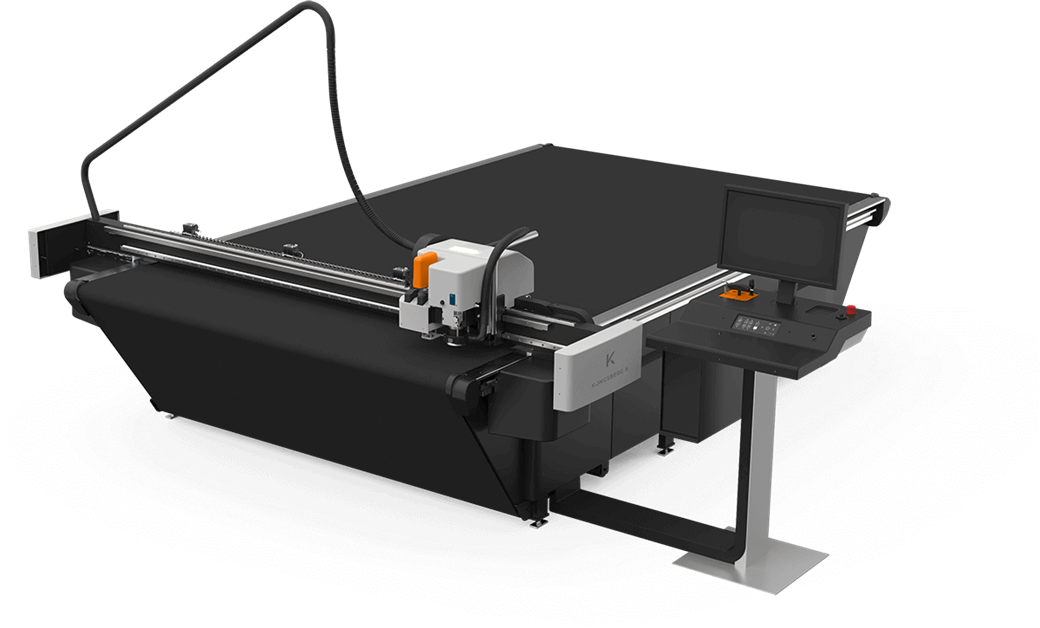

Exchanging different tools is quick and error-free, because every insert is identified by a unique bar code. Specific tuning parameters are stored to avoid expensive operator errors.

Dynamic table mapping provides real time updates to the exact field conditions. Precise automatic z-control during finishing means less damage to the underlay.

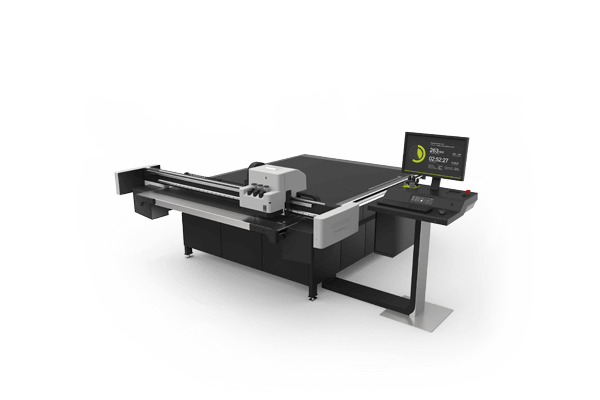

The Kongsberg X Series offers the raw strength required to process even the most rugged materials at high-production speeds. Kongsberg X t ables will keep on going when others might quit.

The Kongsberg X series features the famous, rock-solid Kongsberg tabletop construction that will never warp or go out of level, even after decades of heavy use.

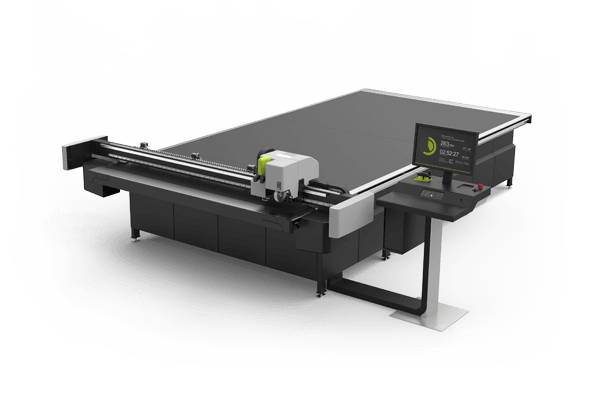

The front-end turns the Kongsberg X into the most flexible cutting table on the market today. The i-cut Production Console offers users powerful functionality for signage, display and packaging production.

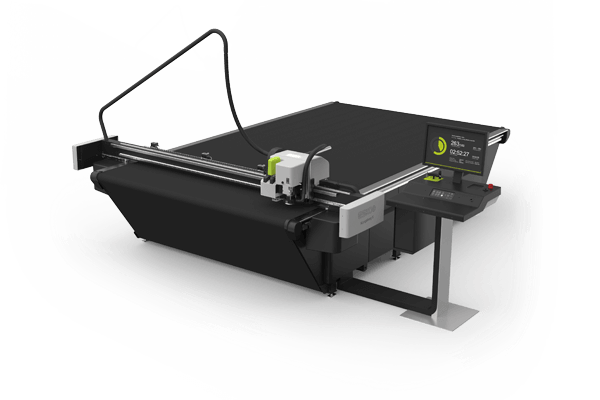

iPC ensures highly efficient production along with extremely accurate print-to-cut registration. The state of the art user interface offers improved usability and there’s personalized job management per operator.

To ensure perfect quality – every time - iPC gives you “shared resources”, using metadata to automatically select the perfect tool for the job, to adjust the hardware and optimize the cutting sequence.

The rack-and-pinion drive system provides speed, durability and strength, drives through dense/thick materials with ease.

Kongsberg X tables can be configured for milling applications ranging from sporadic, light-duty routing to lengthy jobs working with heavy-duty materials — all with record-breaking productivity.

Insert knife tools are available for cutting all relevant materials ranging from thin paper over synthetic sheets to heavy-duty packaging and display material. The tooling selection also includes creasing, plotting and drilling tools.

A set of advanced, quick change toolheads provides unsurpassed versatility, making it easy to set up the machine to process any material for just about any application.

Want to talk to a specialist? Just leave your contact info below and we'll get back to you.