Let's discuss

Want to talk to a specialist? Just leave your contact info below and we'll get back to you.

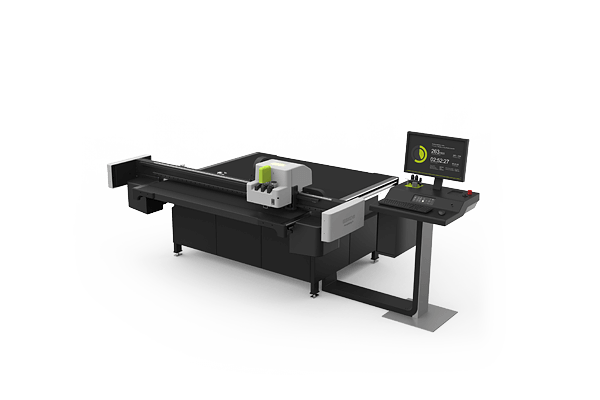

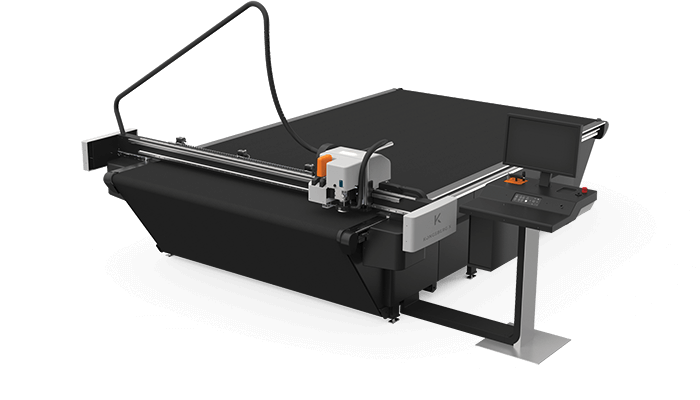

The Kongsberg X Edge is the perfect start of your digital finishing journey. The tried and tested Kongsberg recipe of productivity and flexibility combined with best in class reliability – no compromise.

The Kongsberg X Edge delivers speeds of 30 m/min with acceleration of 0.3G and can handle the full spectrum of display, signage and packaging materials from kiss cutting vinyl to heavy duty milling…and everything in between.

As your company grows, the Kongsberg X Edge evolves with you and can be easily upgraded in both speed and acceleration to ensure it keeps up with your business demands.

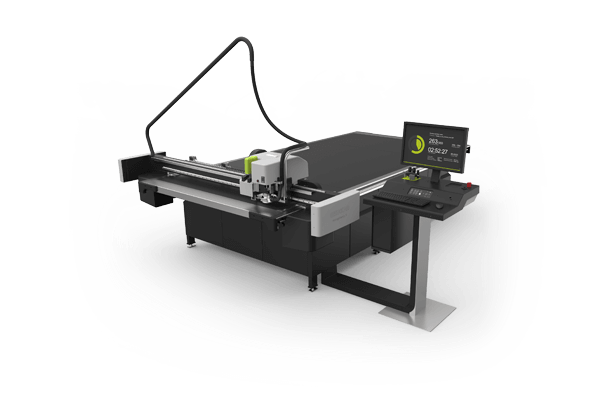

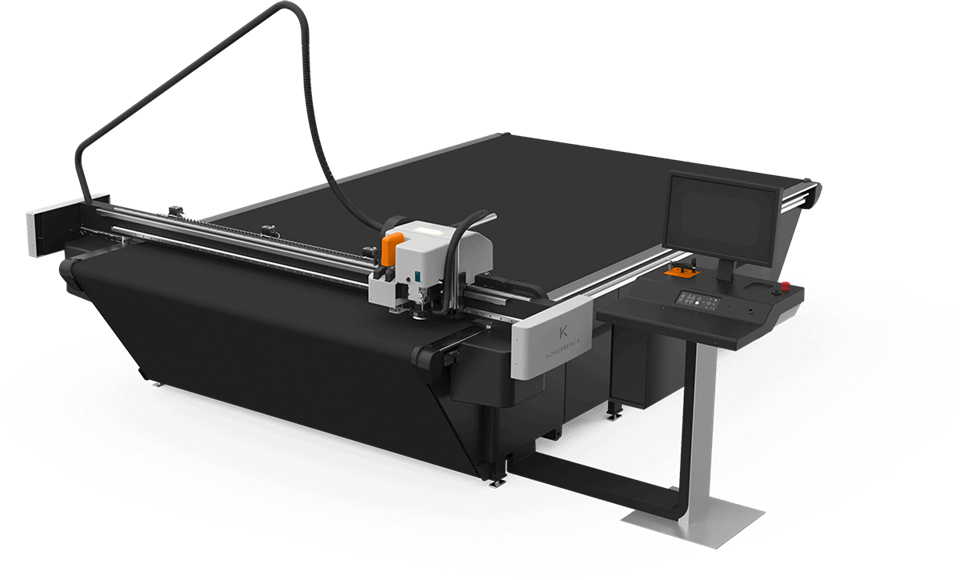

Exchanging different tools is quick and error-free, because every insert is identified by a unique bar code. Specific tuning parameters are stored to avoid expensive operator errors.

Dynamic table mapping provides real time updates to the exact field conditions. Precise automatic z-control during finishing means less damage to the underlay.

The Kongsberg X Edge Series offers the raw strength required to process even the most rugged materials at high-production speeds. Kongsberg X Edge tables will keep on going when others might quit.

The Kongsberg X Edge series features the famous, rock-solid Kongsberg tabletop construction that will never warp or go out of level, even after decades of heavy use.

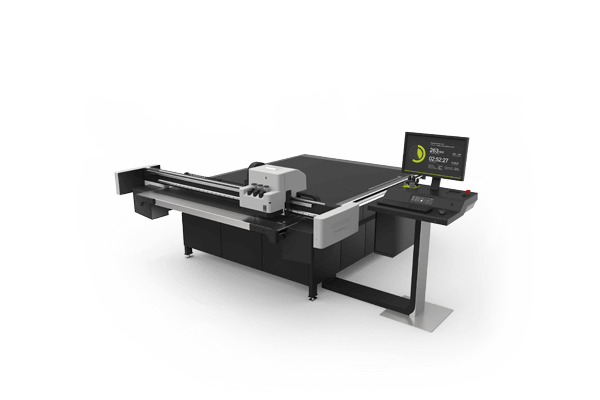

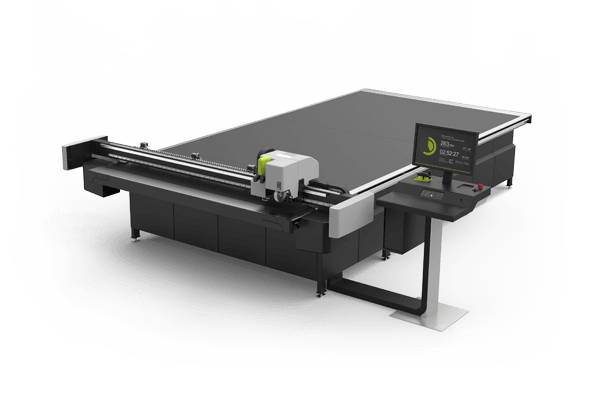

The front-end turns the Kongsberg X Edge into the most flexible cutting table on the market today. The i-cut Production Console offers users powerful functionality for signage, display and packaging production.

iPC ensures highly efficient production along with extremely accurate print-to-cut registration. The state of the art user interface offers improved usability and there’s personalized job management per operator.

To ensure perfect quality – every time - iPC gives you “shared resources”, using metadata to automatically select the perfect tool for the job, to adjust the hardware and optimize the cutting sequence.

The rack-and-pinion drive system provides speed, durability and strength, drives through dense/thick materials with ease.

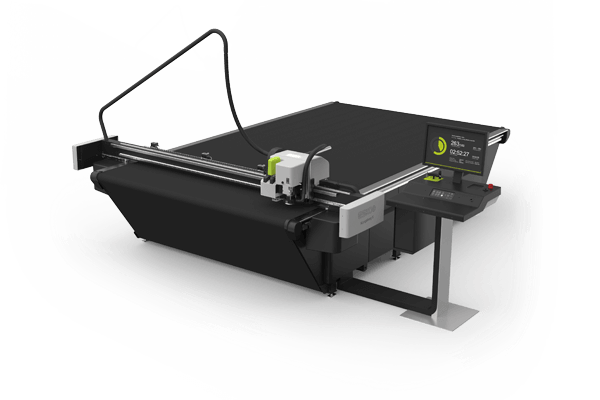

Kongsberg X Edge tables can be configured for milling applications ranging from sporadic, light-duty routing to lengthy jobs working with heavy-duty materials — all with record-breaking productivity.

Insert knife tools are available for cutting all relevant materials ranging from thin paper over synthetic sheets to heavy-duty packaging and display material. The tooling selection also includes creasing, plotting and drilling tools.

A set of advanced, quick change toolheads provides unsurpassed versatility, making it easy to set up the machine to process any material for just about any application.

Want to talk to a specialist? Just leave your contact info below and we'll get back to you.