Let's discuss

Want to talk to a specialist? Just leave your contact info below and we'll get back to you.

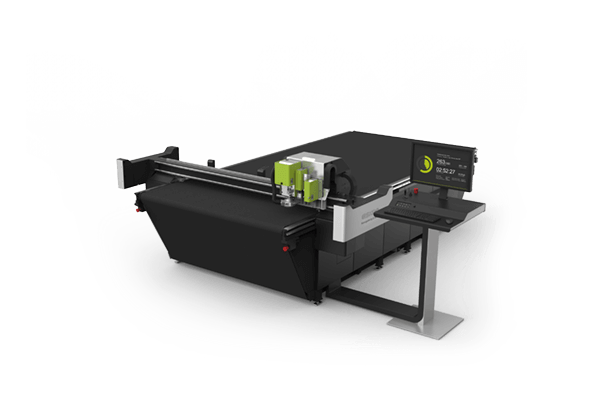

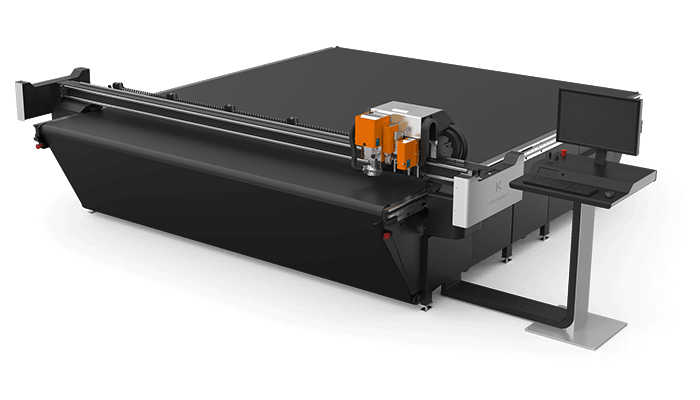

The Kongsberg C is specifically designed to operate continuously in a 24/7 production environment.

The machine smoothly handles all frequently used substrates, even the most rigid materials, at record breaking speed. This makes it the table of choice for all signage, display and packaging applications.

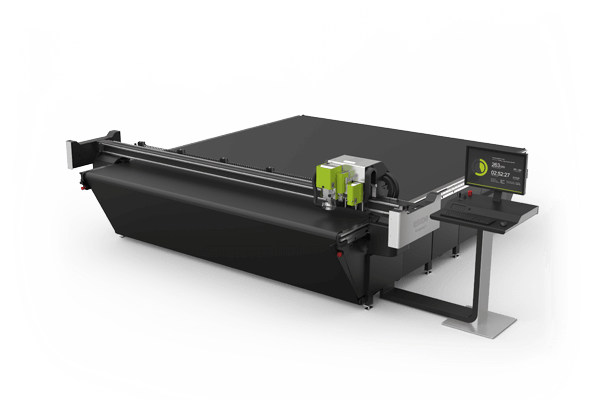

Dynamic table mapping provides real time updates to the exact field conditions. Precise automatic z-control during finishing means less damage to the underlay.

The Heavy Duty Tool Unit offers 500N / 110lbs of down force, sufficient to crease even the most challenging materials.

The Kongsberg C series features the famous, rock-solid Kongsberg tabletop construction that will never warp or go out of level, even after decades of heavy use.

The front-end turns the Kongsberg C into the most f lexible cutting table on the market today. The i-cut Production Console offers users powerful functionality for signage, display and packaging production.

iPC ensures highly efficient production along with extremely accurate print-to-cut registration. The state of the art user interface offers improved usability and there’s personalized job management per operator.

To ensure perfect quality – every time - iPC gives you “shared resources”, using metadata to automatically select the perfect tool for the job, to adjust the hardware and optimize the cutting sequence.

Provides speed, durability and strength, drives through dense or thick materials with ease.

The new auxiliary control panel at the end of the traverse offers easy access for the operator, speeding up production.

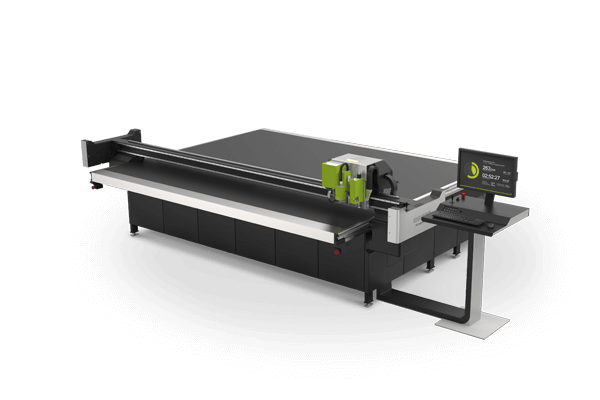

Kongsberg C tables can be configured for milling applications ranging from sporadic, light-duty routing to lengthy jobs working with heavy-duty materials — all with record-breaking productivity.

A complete set of advanced, quick change tools provides versatility, making it easy to set up the cutting table to process any material.

The extreme rigidity of carbon makes the traverse capable of high speeds, accuracy and heavy payload, even when working on the most demanding materials.

Want to talk to a specialist? Just leave your contact info below and we'll get back to you.