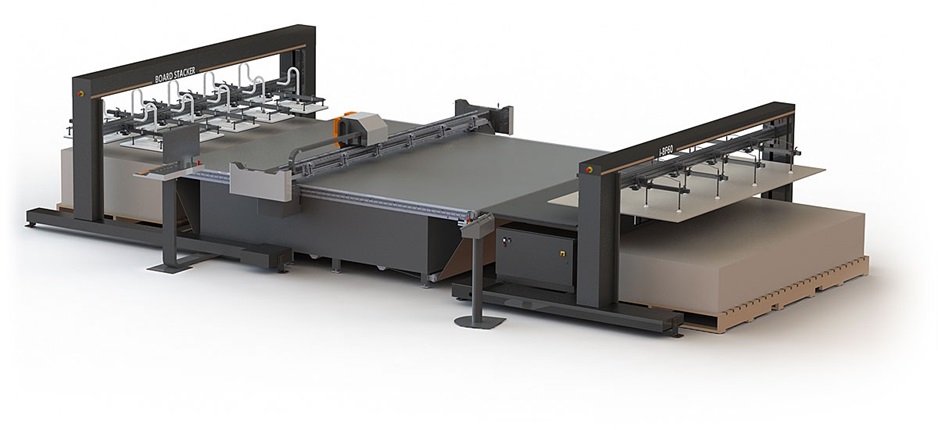

Display Production

POP/POS displays are an important part of any marketing mix. Producing eye-catching displays requires a cutting table that can handle a wide range of materials, some of them very demanding. The more diverse material the table can handle, the more creative you can be!

What do you need most for your signage production: speed, range, quality, or workflow?

Download this practical ebook with 5 strategies to maximize ROI.