Our heritage. Your future.

For 60 years, we’ve been helping businesses succeed through precision, performance, and strong partnership. Our legacy of innovation and expertise continues to shape the future for customers across the world.

It all began with technology that allowed our customers to work with accuracy and confidence. That commitment continues today, through our people, our innovation, and our focus on helping businesses to succeed now and in the future.

Watch the video

From pioneering computerized plotting for shipbuilders to enabling high-precision performance in packaging, display, signage, and manufacturing, we have always evolved to help our customers maximize productivity and unlock their full potential.

Explore our heritage

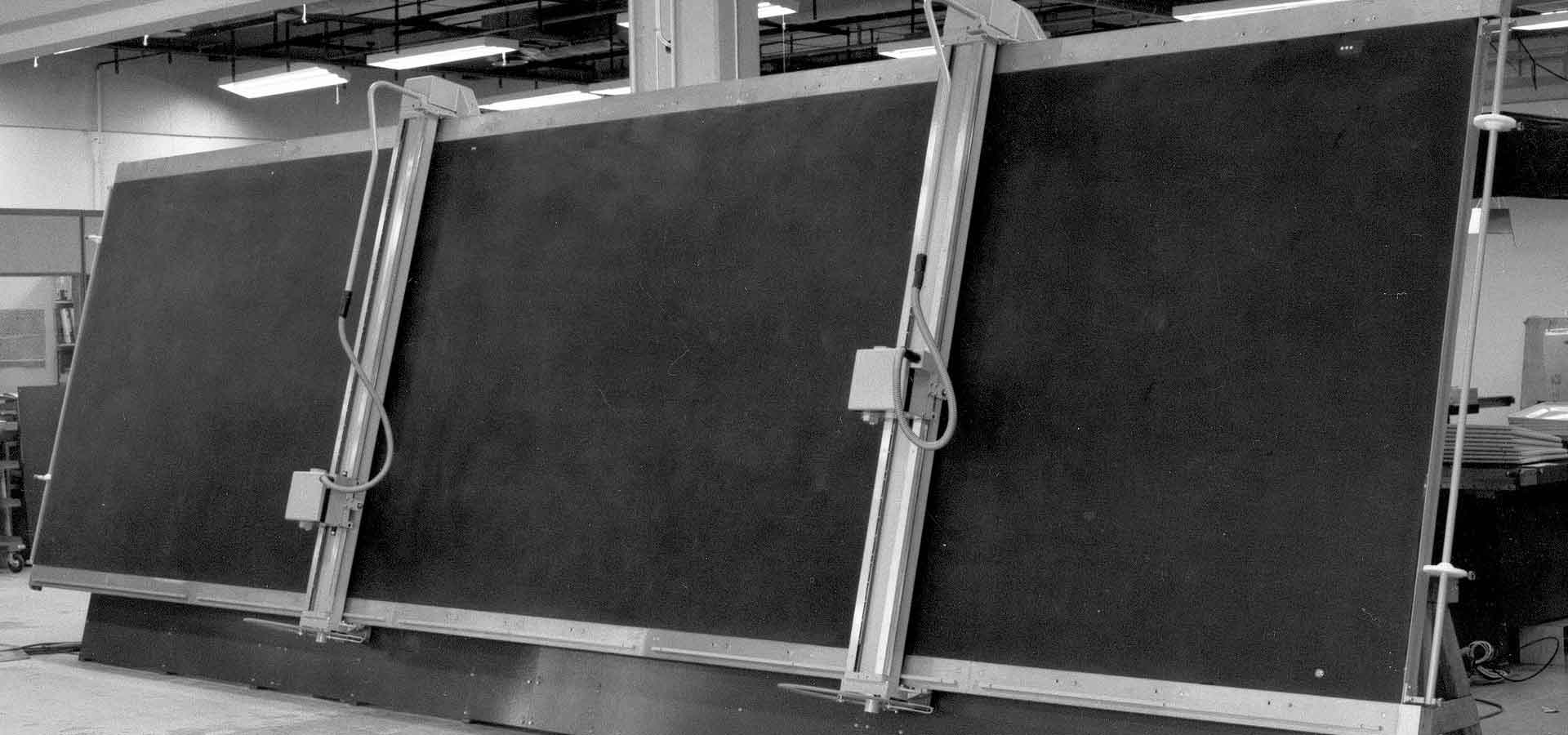

1965

Kongsberg pioneered some of the first computerized plotting tables for shipbuilders, which were later developed into high-precision film engravers for map and automotive manufacturers. This foundation led to the creation of cutting, creasing, and advanced finishing systems that now drive productivity and precision in the packaging, signage, display, and manufacturing industries.

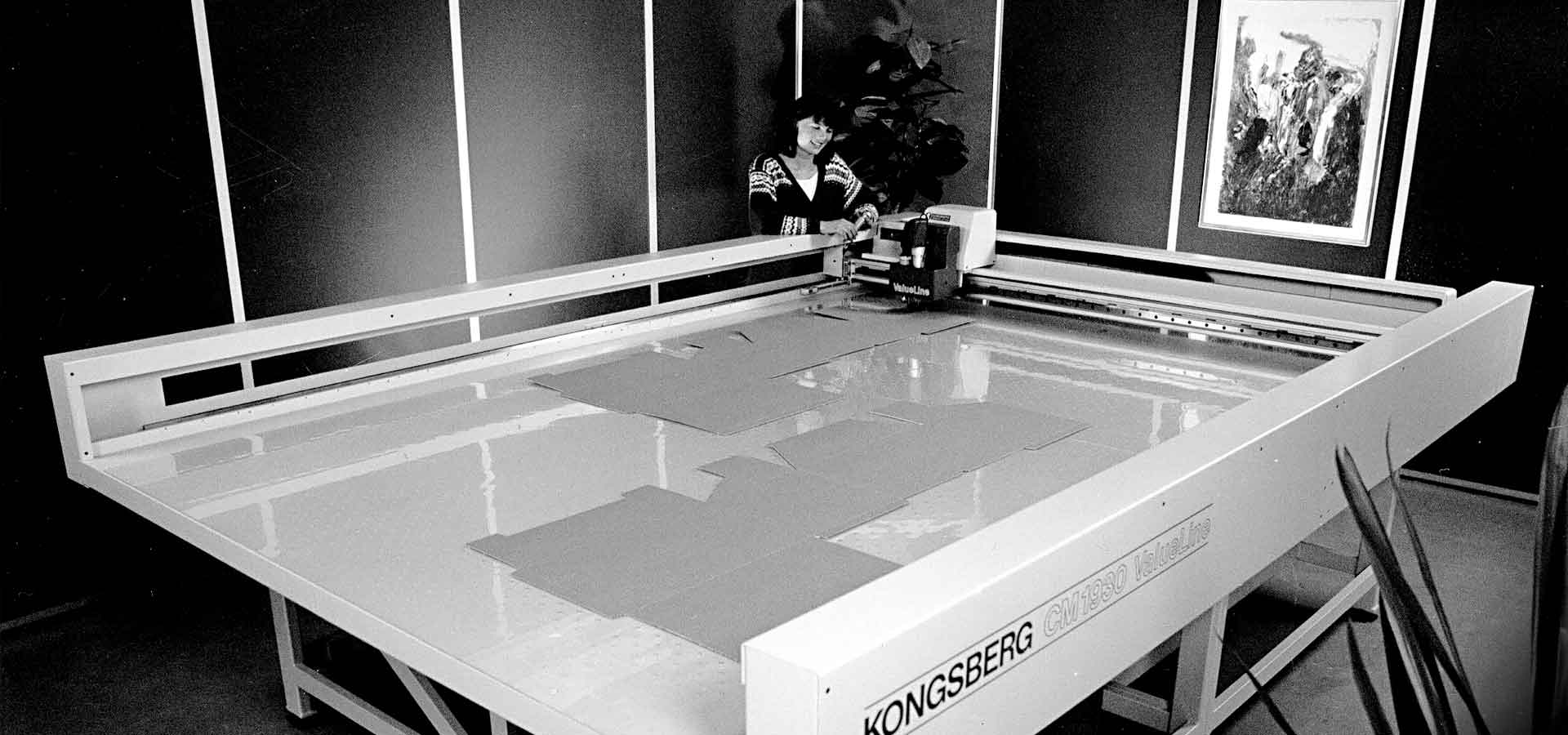

1989

Kongsberg launched the first dedicated packaging sample maker systems, setting a new benchmark for the packaging segment. Designed to streamline prototyping and speed up design validation, these systems empowered professionals to bring concepts to life with greater speed, accuracy, and confidence.

2000

With the XL, Kongsberg introduced a new era of die-less cutting, with a versatile tooling system that handled an unmatched range of materials. It maximized productivity, expanded creative potential, and set a new standard for flexible, high-performance digital finishing.

2001

Barco-Graphics became Esko-Graphics, further solidifying its position as a leading force in the packaging industry. This evolution marked a continued commitment to innovation, integration, and delivering end-to-end solutions that meet the growing demands of packaging professionals worldwide.

2004

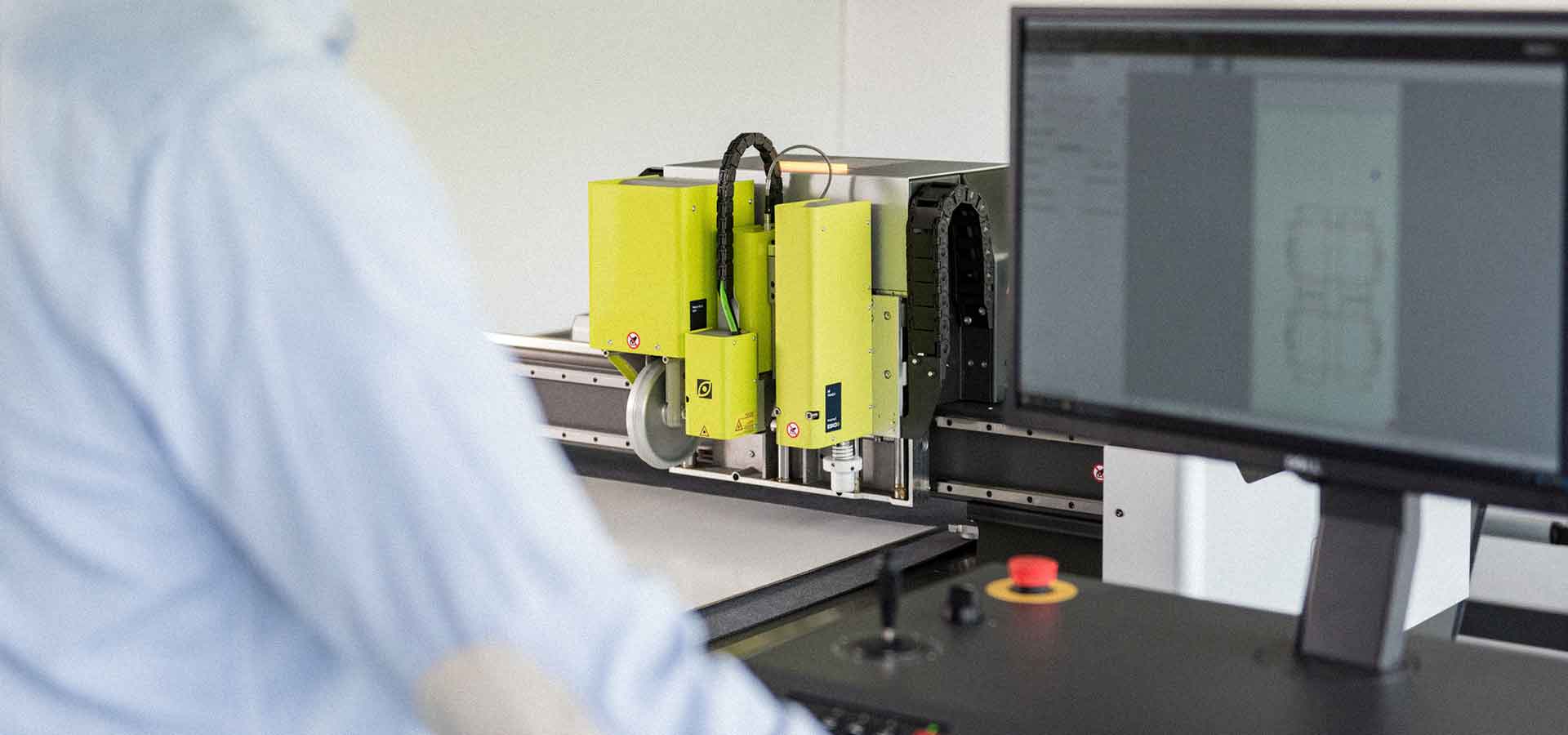

With the i-XL, Kongsberg introduced the first cutting system equipped with an i-cut Vision camera system, marking a pivotal shift toward a more automated future. By eliminating manual steps and streamlining registration, the i-XL set a new standard for precision, efficiency, and intelligent production.

2014

With the release of i-cut Production Console and the C Series, Kongsberg set new benchmarks for ease of use and productivity, combining intuitive controls with powerful performance to streamline operations and boost output across applications.

2016

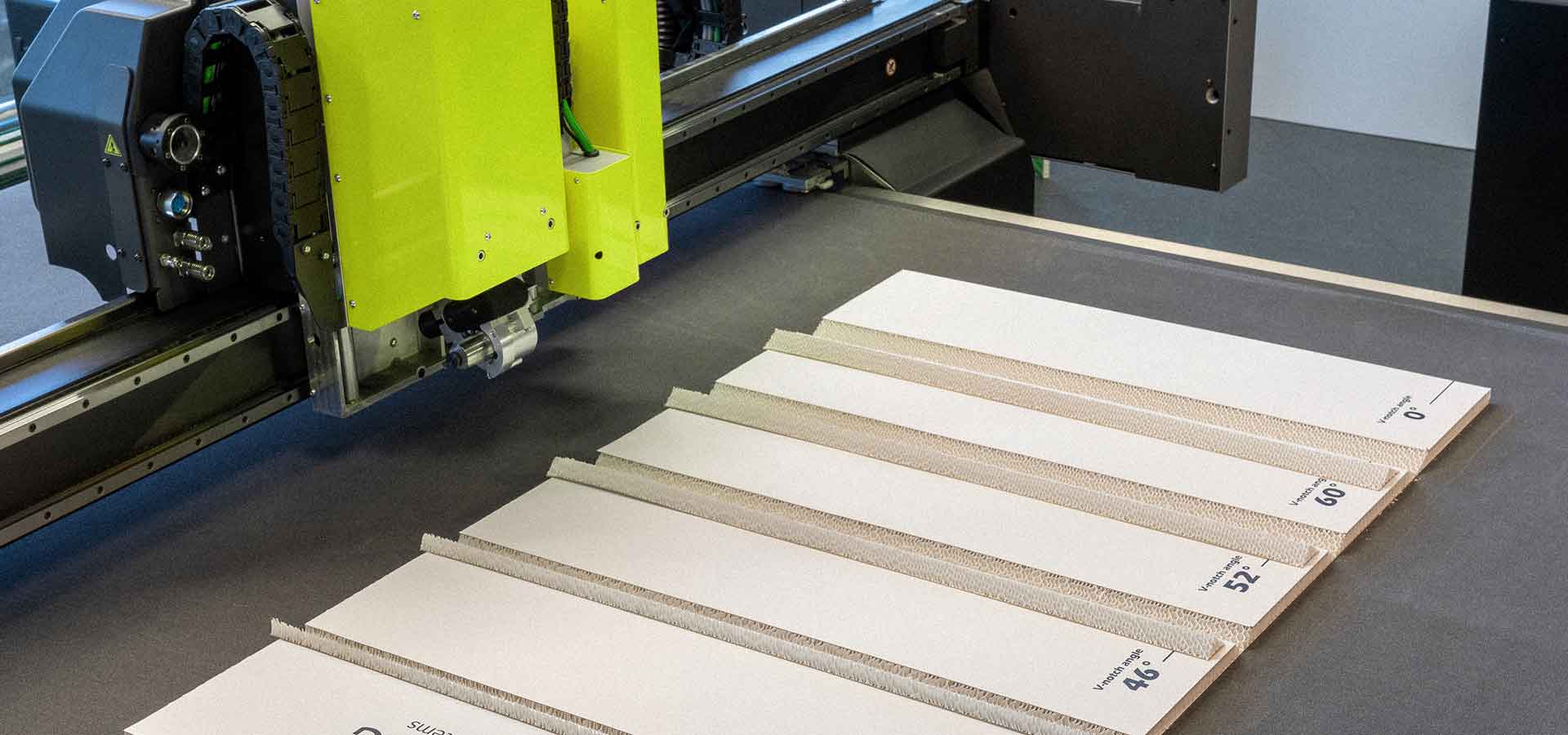

Kongsberg introduced the CorruSpeed tool for flawless, high-speed cutting on corrugated material, delivering clean edges without crushing. Alongside it, the Feeder & Stacker system was launched to boost productivity and free up operator time, enabling continuous, efficient production with minimal manual intervention.

2020

The release of the VariAngle Unit brings new levels of creative freedom, enabling automatic angle cutting without manual tool changes. It expands design potential, boosts productivity, and allows users to take on more complex, high-value applications with ease.

2021

OpenGate Capital acquired the Kongsberg digital finishing division from Esko, establishing Kongsberg PCS as a stand-alone company focused on innovation and growth.

2021

Later that year, Kongsberg PCS expanded its capabilities with the acquisition of MultiCam, a US-based manufacturer and distributor of CNC cutting solutions, broadening its portfolio and reinforcing its position as a global leader in digital finishing technology.

2023

Kongsberg PCS launched the Kongsberg Ultimate, a breakthrough solution that redefined the future of corrugated production. Engineered for unmatched productivity, this next-generation system delivers the speed, precision, and reliability needed to meet the demands of high-volume, high-quality packaging environments.

2025

Kongsberg PCS marked its 60th anniversary by celebrating a legacy of innovation and customer partnership, while focusing on the future. With continued dedication to productivity, creativity, skilled performance, and business-driven solutions, Kongsberg PCS remains at the forefront of digital finishing.

Discover the innovations driving smarter, faster, and more efficient cutting today, and see how we can support you in shaping what comes next for your business.

Learn what drives us

Our systems are built to keep your business moving. With high-speed performance, intelligent software, and robust engineering for dependable uptime, we offer remote support and tailored configurations to deliver productivity without compromise.

Our solutions are built for versatility, supporting a wide range of materials and applications across diverse markets. With adaptable tooling, expert guidance, and long-term support, we help you stay competitive, meet changing demands, and maximize your investment.

Our systems help you unlock new opportunities by enabling exceptional cutting and routing across a wide range of materials. Engineered for performance and versatility, our solutions support expansion into new markets, deliver premium quality, and create a point of difference that helps attract high-value customers and drive growth.

Our technology is designed to free your skilled operators to focus on what matters most. Reliable systems, intuitive operation, and scalable automation reduce routine tasks and maintenance, allowing teams to apply their expertise where it creates the greatest value.

Our customers are at the heart of every innovation. From productivity breakthroughs to new market opportunities, businesses are achieving more with Kongsberg.

Discover their stories

"With the Kongsberg C, the speed at which we can now run blades through materials has tripled. This significant increase has enabled us to also save on both manual labour and material waste."

"We can work three shifts on it, five days, six days; sometimes when we have huge orders, even seven days per week - without any problem."

"The MultiCam Apex3R has already come close to paying for itself in terms of the labor it saved and the quality of the belts we’re putting out."

"Everyone here knows how to use the Kongsberg X and they use it freely for innovation. Whatever idea they have, they design it on the computer and in a few minutes they can have it in real scale, try it and improve it."

"Once we had our first Kongsberg in, we started to understand how it was helping us – how it was helping our profitability, and helping us offer something new that we could show our clients."

"The combination of high-speed cutting with the automated board feeding ensured we were able to increase our overall production capacity."

"One of the benefits since installing the Kongsberg is that we have definitely gained new customers, with new products that we didn't have before."