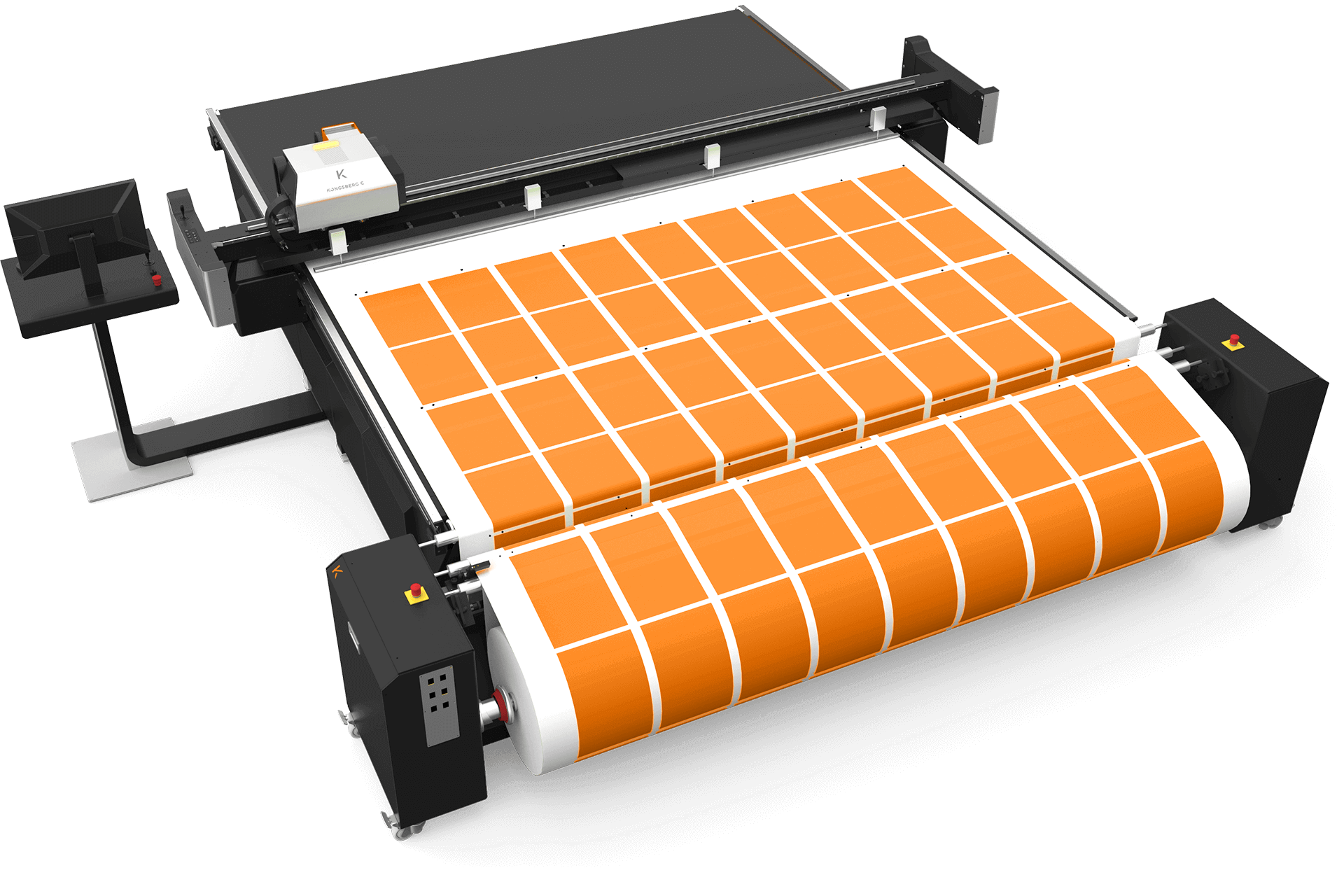

Signage Production

Take on more signage jobs with confidence. Kongsberg flatbed cutters handle a wide range of materials and formats with precision and speed, helping you streamline production and deliver high-quality results.

What do you need most for your signage production: speed, range, quality, or workflow?

Download this practical ebook with 5 strategies to maximize ROI.