Kongsberg Digital Cutting Tables: precision engineering to maximize your productivity and ROI

Looking for a smarter cutting solution? Let’s talk!

Looking for a smarter cutting solution? Let’s talk!

Before you pour more time and money into manual workarounds, look at what’s really holding your production back. Below are the most common challenges we hear from our customers... and how a Kongsberg digital cutter removes each bottleneck so you can run faster, safer and more profitably.

Your challenge |

Kongsberg flatbed cutter solution |

|---|---|

| Missed deadlines due to slow manual cutting and bottlenecks in finishing | Slash setup times & run faster – digital cutting with no dies, quick job changeovers, and high-speed production so you hit every deadline. |

| Inconsistent cut quality from job to job | Repeatable precision – automated cutting and tooling deliver consistent, high-quality results on every run, regardless of operator. |

| Long setup times that kill productivity | Minimal prep, maximum uptime – load, select the job, and run. Tool presets and automation reduce setup from hours to minutes. |

| Limited tooling that restricts your creative output | One table, many tools – wide range of tooling to cut, crease, mill, and route everything from corrugated to rigid boards, foam, vinyl, textiles, wood, and acrylic. |

| Safety concerns with older cutting equipment | SmartZone™ safety built-in – advanced safety systems protect operators while keeping production moving. |

| Need to grow capacity without adding headcount | More output, same team – automate repetitive tasks, reduce manual handling, and push more jobs through the same workforce. |

| Unsustainable waste and low margins | Higher profit per job – precision cutting reduces material waste, while higher speed allows more billable work per shift. |

| Unsure if current equipment can keep up as you grow | Scale as you grow – start with a configuration that fits today, then add modular tools, automation, and upgrades as demand increases. |

... you are constantly looking for faster ROI and a scalable investment. See how Kongsberg helps you cut costs and grow profitably.

... you might be struggling with tight deadlines and limited resources. Discover how Kongsberg keeps production smooth and efficient.

... you need tools that are easy to use and are always precise. Find out how Kongsberg makes every job faster and simpler.

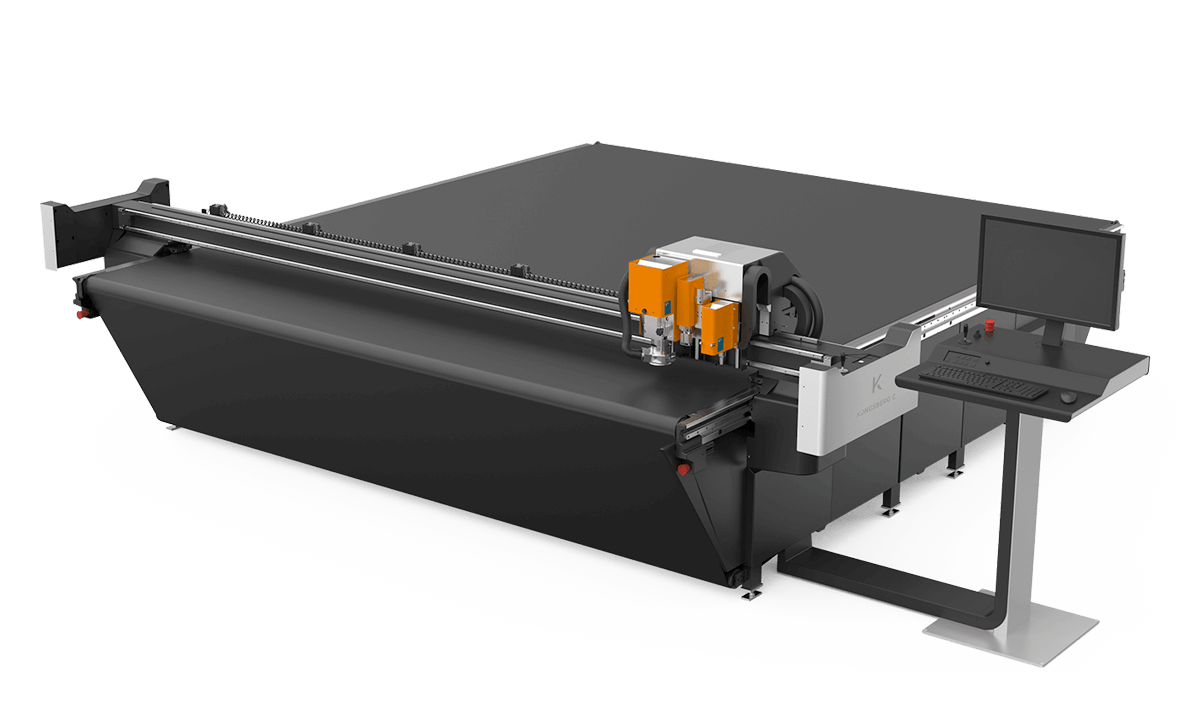

The Kongsberg Ultimate sets a new standard for corrugated and display production. Built for unmatched throughput, it maximizes productivity, solves the toughest high-volume challenges, empowers skilled teams with reliable automation, and unlocks new potential for continuous, profitable growth.

The C Series offers exceptional versatility. From heavy-duty board to lightweight displays, it delivers precise, reliable performance across materials, helping your team adapt quickly, stay efficient, and take on any job with confidence.

Automate manual steps throughout your production.

In the fast-paced world of corrugated marketing, IPC (i-cut Production Console) brings unmatched simplicity and precision to your workflow: it makes every step easier on your Kongsberg cutting table.

Business owners gain confidence knowing jobs run efficiently with less waste. Production managers benefit from smooth planning, live job tracking, and reliable repeatability. Operators enjoy a simple, intuitive interface that handles tool setup, presets, and camera alignment automatically.

The result? Faster turnaround, consistent quality, and more time to focus on growing the business.

The C66 cutting table, complete with the automated Feeder and Stacker, is part of a strategic plan of Embamat to automate the plant.

Packaging and POS specialist MELS Packaging Innovation brings designs to life with Kongsberg table, while automated Feeder & Stacker boosts productivity.

Cartonlab uses Kongsberg table for innovation, creativity & lots of experimentation.

Three Kongsberg PCS machines enable conveyor belt specialist Volta Belting to meet demand while extending capabilities.

Find out how you can use a Kongsberg cutting table to extend on your offerings and protect your margins.