Breakthrough Automation

A range of impressive innovations will boost the performance of digital finishing operations to industrial levels.

Get the most out the Kongsberg C and Kongsberg X cutting tables with these automation options.

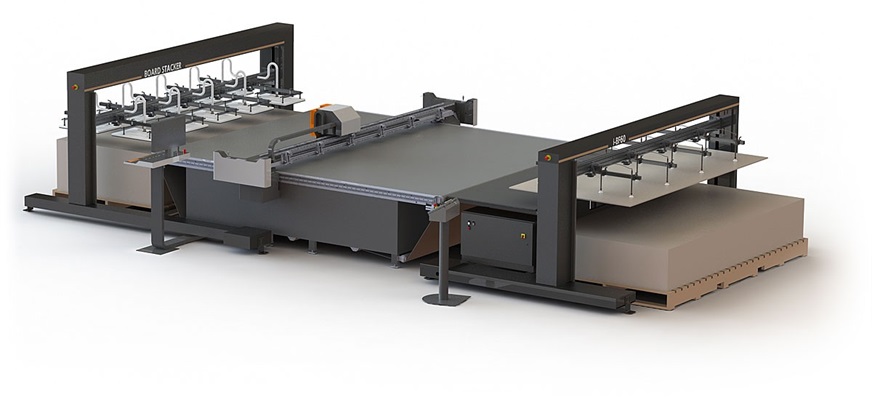

The Kongsberg Automate board feeder and stacker is the perfect way to increase productivity and give your business a competitive edge. It’s an easy to use pallet-to-pallet solution. It feeds corrugated, paper core boards and plastics quickly and accurately from pallet with 2 feed cycles per minute in a continuous material flow. There are no delays loading and unloading boards from the table, so the table is utilized optimally.

The feeder and stacker are developed for the Kongsberg X and Kongsberg C tables. The board feeder (i-BF) and stacker (i-MF) can be purchased separately. An optional roll feeding unit and extension tables are also available.

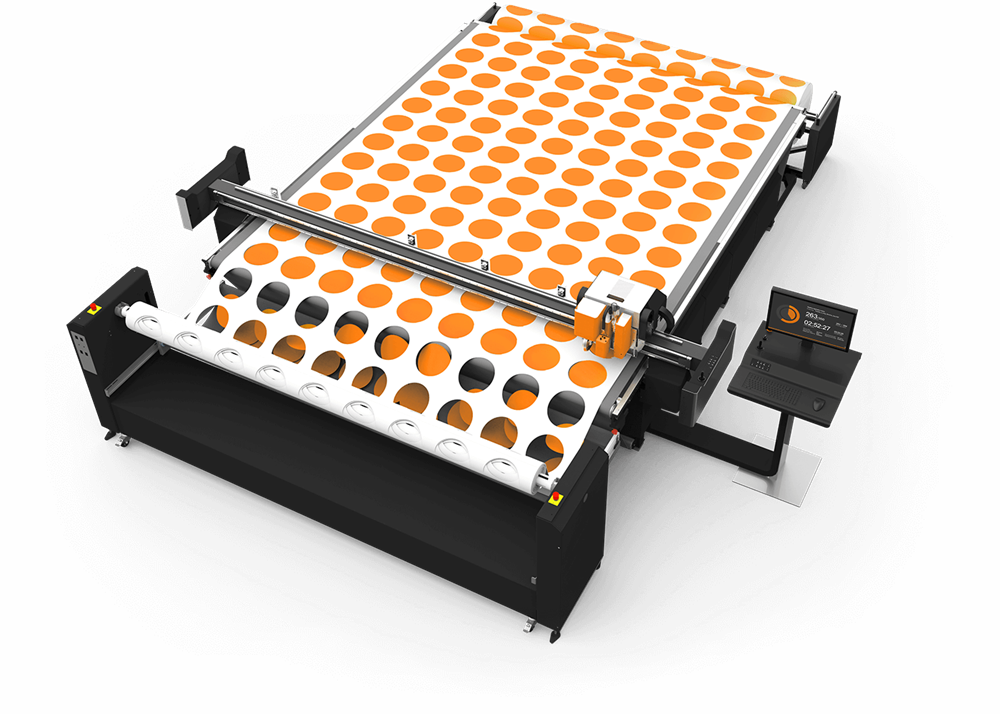

The Robotic Material Handler is a high-capacity material handling system. It’s perfectly matched to the Kongsberg C66R cutting platform and working in combination with 2 or 4 stacks of material, it offers complete unattended operation. The Robotic Material Handler increases productivity while reducing operator time.

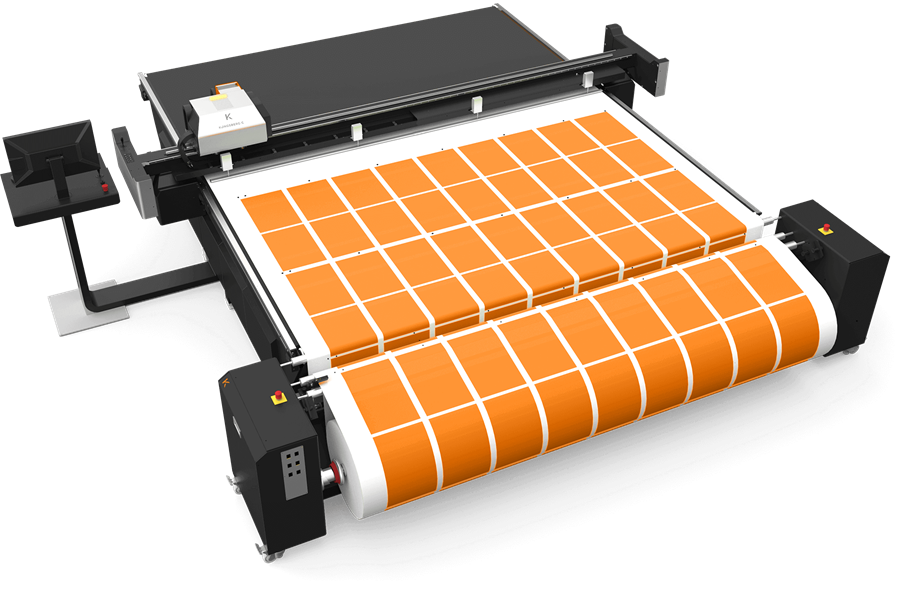

The Kongsberg Motorized Roll Feeder is a wide format roll feeder with active material feed for the Kongsberg C64 cutting table. With the Kongsberg Motorized Roll Feeder you eliminate inaccurate cuts on soft signage materials due to wrinkles, stretch distortion or imperfectly rewound rolls, even on the most challenging and stretchy substrates.

The Kongsberg Motorized Roll Feeder is the only solution in the soft signage industry that guarantees perfect cut results on tensile materials; from the very first cut through to the end of the roll.

Combined with the Kongsberg Take-Up Unit, the Motorized Roll Feeder enables true roll-to-roll production.

The Kongsberg Take Up Unit for flexible materials makes roll to roll workflows easier. The unit makes finishing digitally printed jobs on rolls, and collecting waste, very straightforward.

The Take Up Unit is simple to install for any Kongsberg table equipped with a conveyor feed system. The unit is hassle-free to operate and can easily be moved away when it’s not needed.

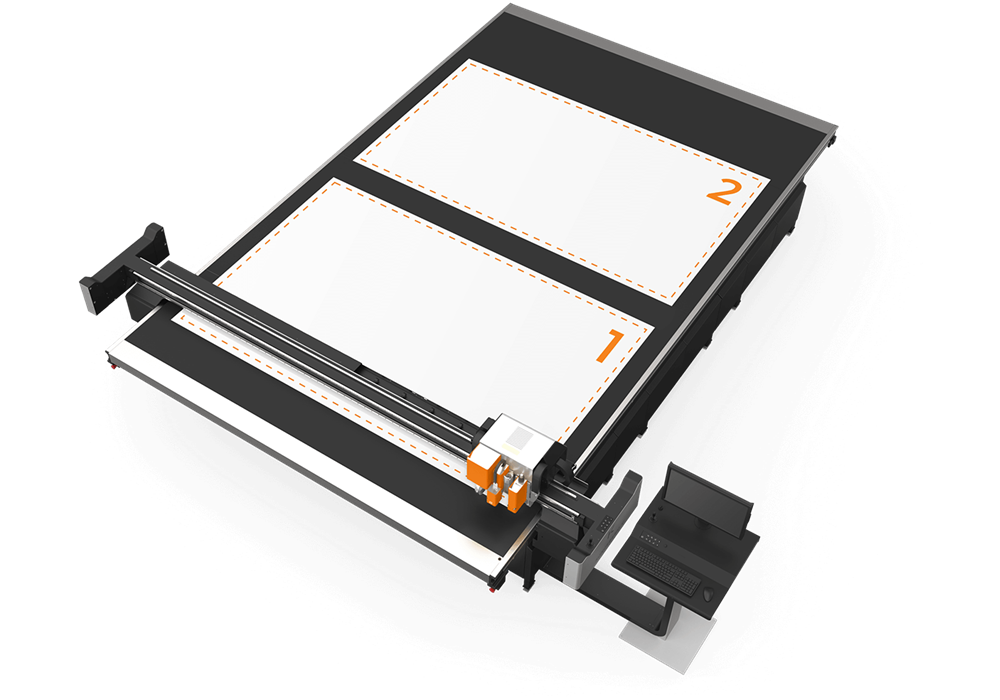

Kongsberg tables are able to work with two work zones independently: multi-zone finishing.

This is particularly useful with the larger Kongsberg tables. While one zone of the table is in action, an operator can set up the other zone by clearing the finished piece and loading a new sheet. While the operator works and prepares one zone, the machine works at the other zone.